Rising fuel costs, changing emissions standards, and aging fleets are pushing more operators to take a closer look at their engine options. For some, that means considering Scania marine diesels.

Scania engines are showing up in more commercial vessels across the U.S. because they’ve proven reliable in real-world use. The best Scania marine engine reviews come from operators who have put them to the test in demanding conditions. This piece outlines what operators can expect from Scania marine engines, including core features, field applications, and support considerations.

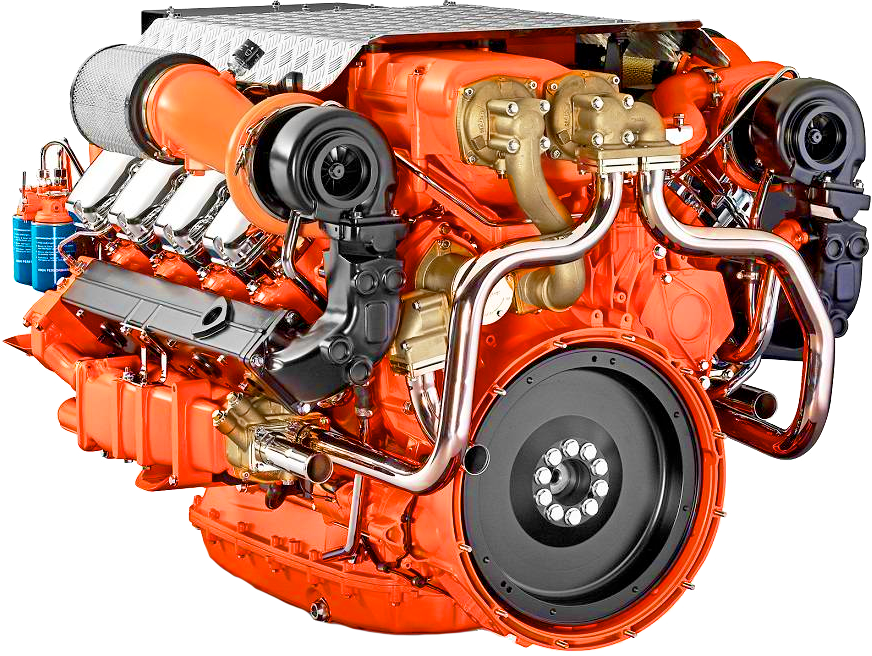

What are the Key Features of Scania Marine Diesel Engines?

Every Scania engine is built around a modular platform, meaning components like blocks, heads, and fuel systems are shared across engine families. For operators, that translates to fewer unique parts to stock, simpler maintenance planning, and more consistency across fleets running multiple engine models.

Despite their compact footprint, Scania marine engine specifications deliver a high power-to-weight ratio. That makes them a practical fit for vessels with tight engine rooms or weight-sensitive applications like crew boats and pilot vessels, where performance can’t come at the cost of space or balance.

Scania’s approach to engine management pairs mechanical durability with precise electronic control. Their in-house engine control unit (ECU) monitors fuel delivery, boost pressure, and exhaust temperature in real time to help crews achieve maximum efficiency without constant manual adjustment.

Emissions compliance is another factor. Scania offers US Tier 3 marine and IMO Tier III options, with aftertreatment systems that are built into the engine rather than added on later. The result is a cleaner burn and a simpler path to compliance, particularly for operators planning ahead for regulatory shifts.

Finally, Scania doesn’t outsource its fuel injection systems. The high pressure common rail setup is developed and built in-house, giving the manufacturer tighter control over efficiency, emissions, and performance at low RPMs. That’s especially important in applications with variable loads or extended idle time.

What are the Fuel Efficiency Benefits of Scania Marine Engines?

Fuel costs are one of the most persistent expenses in marine operations. For high hour vessels running daily routes, even small gains in efficiency can lead to significant savings over time.

Scania marine engines are built with that in mind. The system is designed to reduce waste and improve burn consistency across a wide range of conditions. Rather than running rich across the board, the system fine tunes combustion in real time to maximize efficiency.

Compared to older mechanical engines or early-generation electronic platforms, many operators have seen measurable improvements in fuel economy, particularly in vessels that cycle between idle, low-speed maneuvering, and sustained high-RPM operation. The ability to maintain performance without over fueling helps cut unnecessary consumption in mixed-use profiles.

Over the course of a season, that efficiency extends range, reduces fill ups, and helps operators maintain tighter refueling schedules. These are practical advantages that go beyond the numbers on a spec sheet.

Are Scania Marine Engines Suitable for Commercial and Recreational Vehicles?

Scania marine engines are most commonly used in commercial vessels, where uptime, performance, and fuel efficiency are critical. While they are not typically found in small recreational boats, they may be considered for larger private vessels or yachts that demand commercial grade durability.

YOU'LL FIND THEM POWERING:

Across these applications, operators rely on engines that can hold torque through a wide RPM band. Scania’s torque delivery is consistent, particularly in the midrange, which makes it easier to maintain speed on plane without overworking the engine.

Durability is another factor. These engines are built for high-use cycles, not light duty intervals. Whether you're putting in long hours offshore or running short hauls throughout the day, the platform is designed to handle repetitive stress without drifting out of spec or forcing unscheduled maintenance.

How Does Laborde Products Support Scania Marine Engines?

For operators running Scania marine engines, parts access is a practical concern. Laborde stocks high-demand components regionally, cutting down on long lead times and helping keep routine maintenance on track. That includes filters, sensors, fuel system parts, and other high demand Scania marine engine parts crews expect to replace on schedule.

Support doesn’t stop at the sale. As one of the trusted Scania marine distributors, Laborde works directly with shipyards and operators during installation and repower projects, staying involved through fit-up and performance validation. That same familiarity with Scania platforms extends into ongoing service, which helps crews stick to the right maintenance intervals and troubleshoot issues when needed.

For fleets working tight schedules, it’s about knowing who to call when something goes off spec and getting a response that’s based on real familiarity with the engine in question.

How do Scania Engines Compare to Other Marine Diesel Options?

For operators weighing engine platforms, Scania marine engine specifications often stand out against traditional mechanical diesels or heavier electronically controlled models. It offers a lighter footprint, more efficient fuel use, and built-in emissions support without sacrificing reliability.

Scania marine engines tend to make the most sense in vessels that need consistent midrange power, compact packaging, and tight control over fuel consumption. That includes operators running fast response or high cycle routes where vessel layout and weight restrictions shape engine selection.

They're also a strong fit for operators preparing for future emissions compliance. With both IMO and US Tier 3 options available, Scania gives fleets a path forward without a major redesign. That flexibility makes it easier to stay compliant across different regions or contracts without locking into a single exhaust aftertreatment strategy.

Scania engines are also being considered more often when operators are dealing with aging platforms that have become harder to support. It's not always about making a switch. It's about finding the right match for the next vessel, especially when parts availability, weight limits, or vessel layout rule out bulkier alternatives.

Scania isn’t a catch-all solution, but in the right application, it aligns well with the priorities operators face today: efficiency, compliance, reliability, and service access that doesn’t require a complete overhaul.