Mitsubishi marine engines and Twin Disc transmissions are built to handle hard, high-hour work. Operators across the inland market pair them because the combination delivers consistent power, reliable shifts, and solid long-term performance. Choosing the right transmission means looking beyond specs. It comes down to how well the system performs under pressure, how easy it is to maintain, and how quickly you can get parts when something breaks.

In this blog, we’ll look at how Twin Disc transmissions complement Mitsubishi engines in real-world conditions and what to know before you plan your next repower or a new build.

How Do Twin Disc Transmissions Enhance Mitsubishi Marine Engine Performance?

The pairing of Twin Disc transmissions and Mitsubishi marine engines is one of the most field-tested setups that Laborde Products supplies.

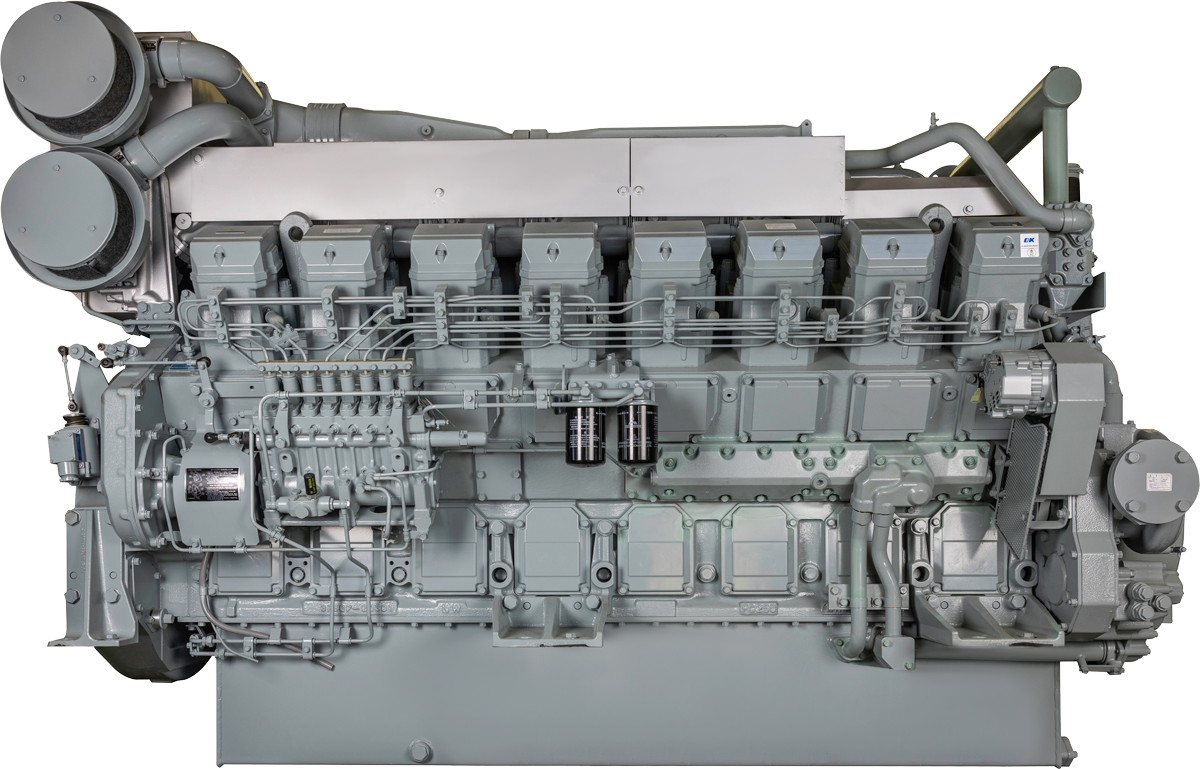

Twin Disc marine transmissions are commonly matched with Mitsubishi’s S6R, S12R, and S16R mechanical diesel engines, offering a range of gear reduction ratios that complement the torque curves and RPM bands of these engines.

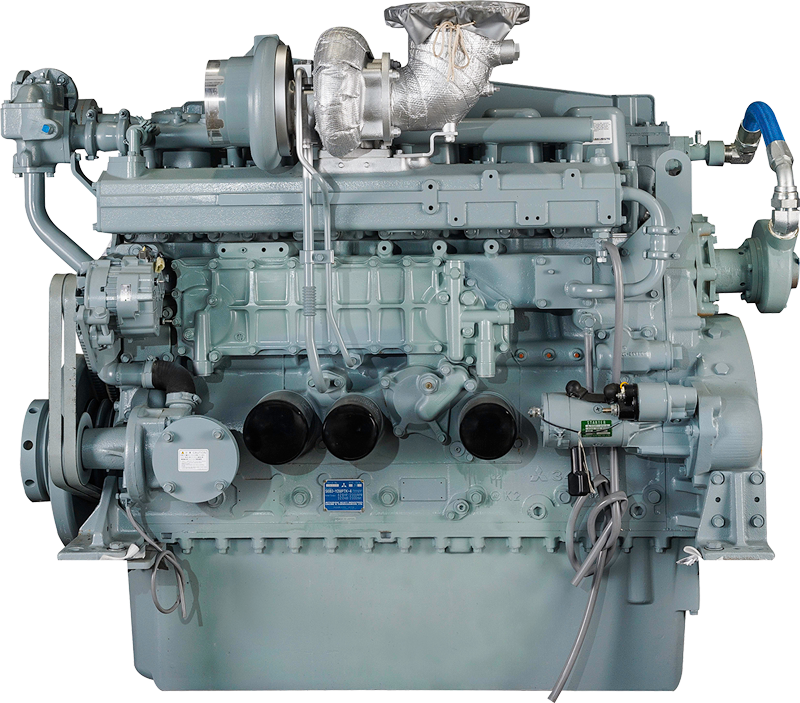

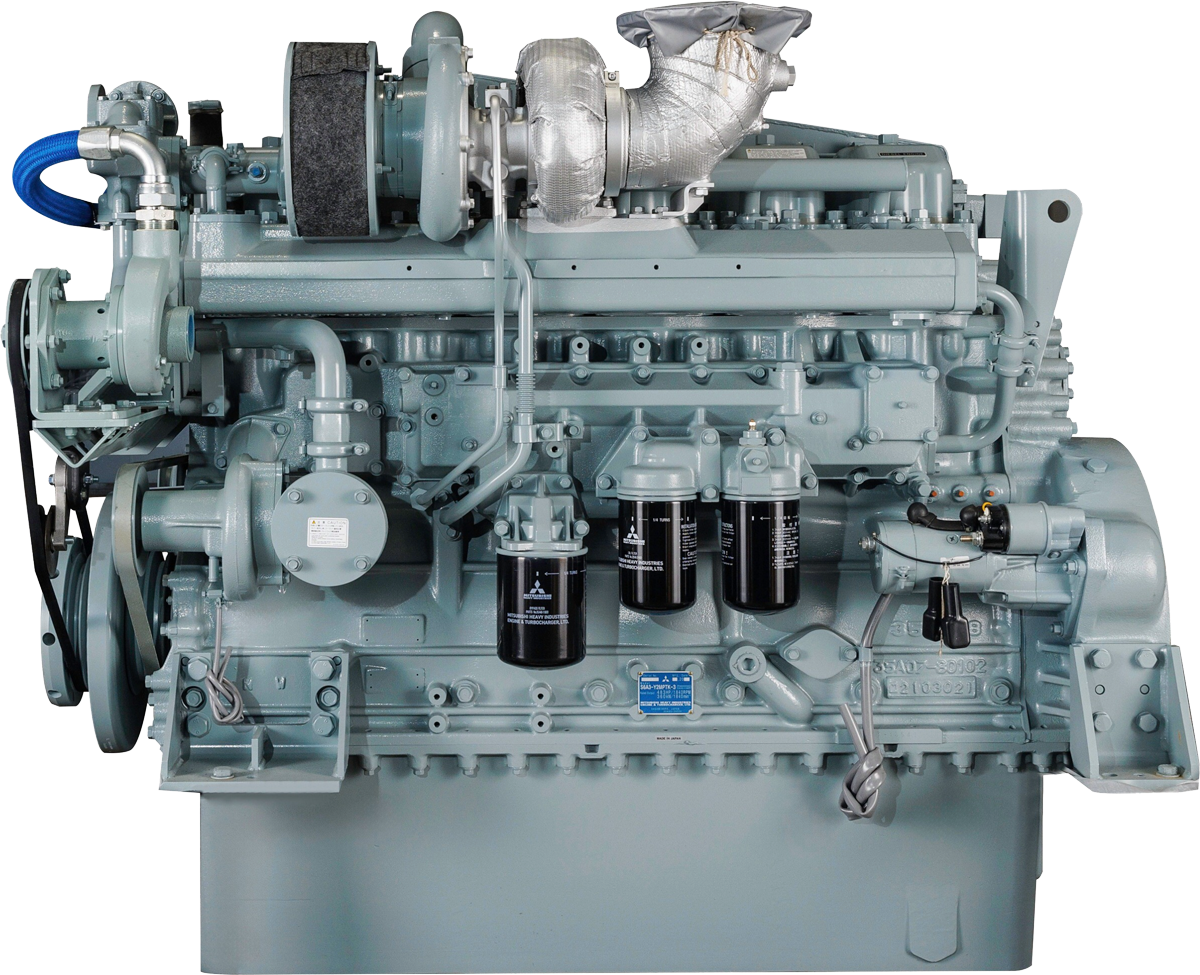

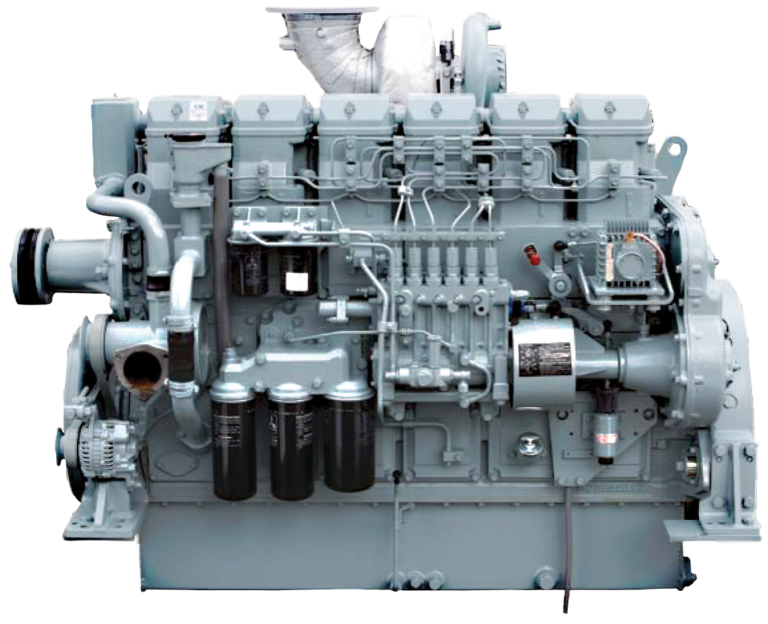

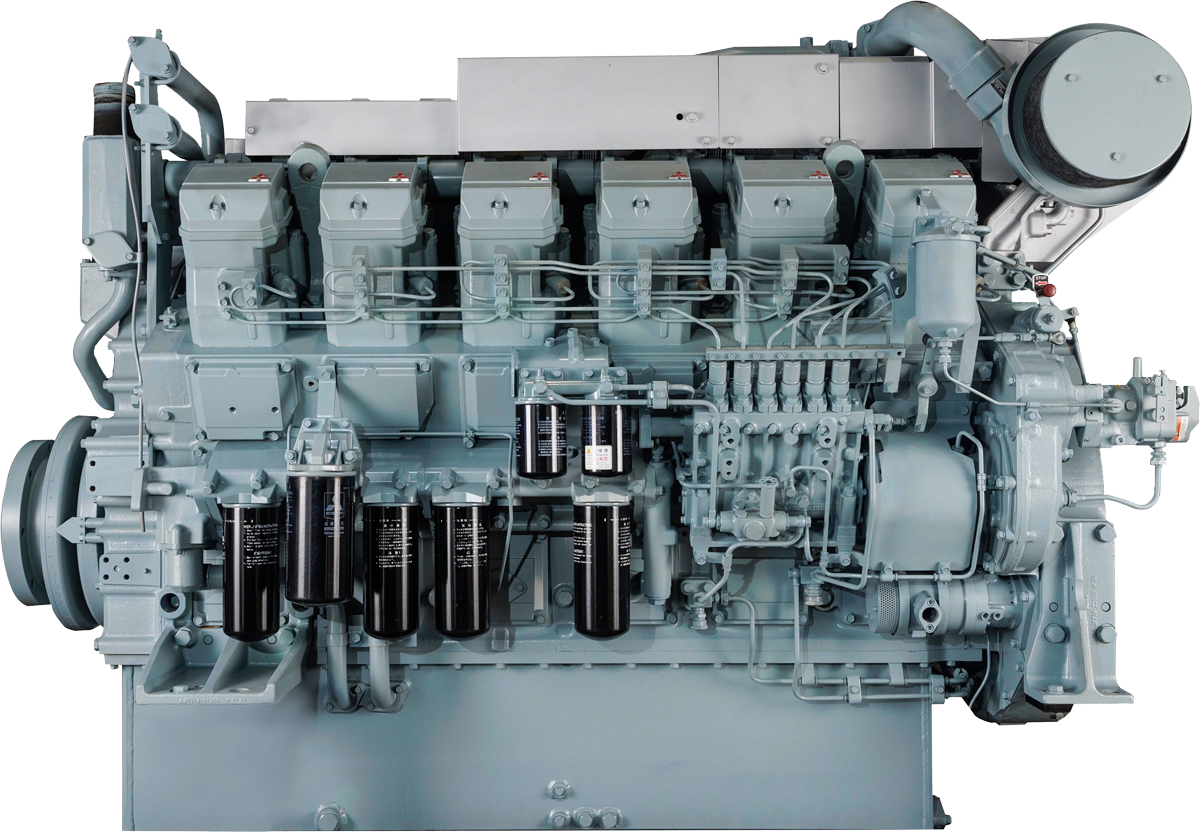

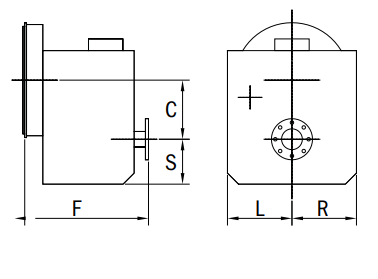

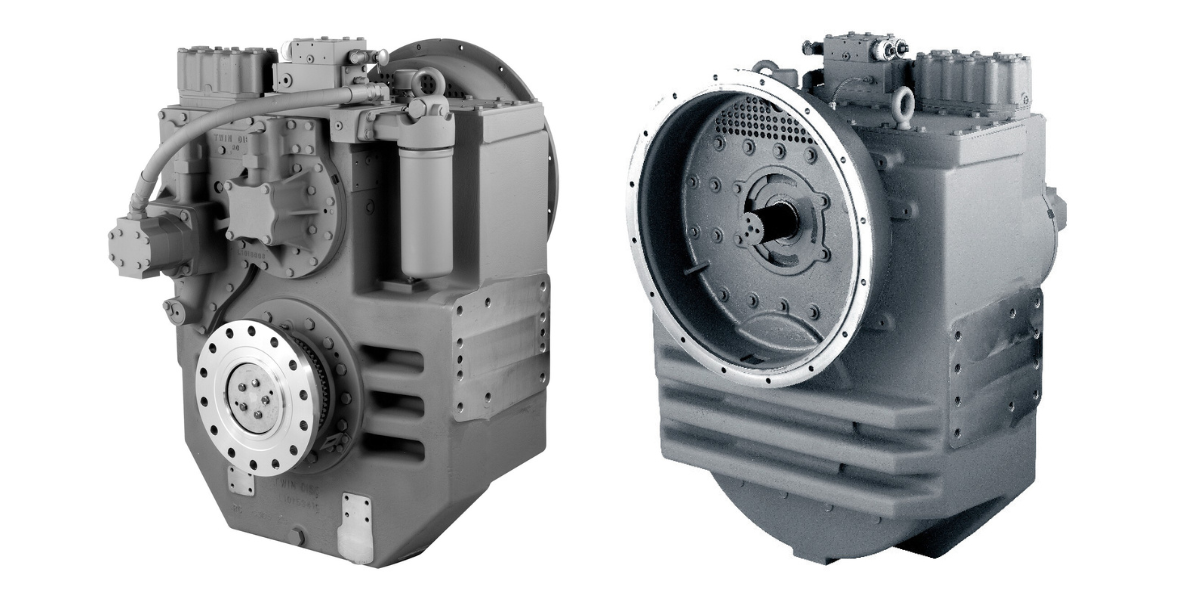

Twin Disc MGX-5321DC

Twin Disc MGX-5321DC

For example, the MGX-5321DC is often paired with the Mitsubishi S6R2, while the MGX-5600 is a strong match for the S12R platform. Whether you’re running a push boat, dredge, or passenger vessel, the integration between the engine and gearbox is clean, proven, and well-supported across the inland market.

From a mechanical standpoint, Twin Disc marine transmissions are engineered to transfer high torque loads at low speeds, which is exactly where Mitsubishi engines perform best. These gearboxes resist slippage and provide smooth clutch engagement under variable loads. That’s especially important in stop-start operations like barge maneuvering, dredging, or harbor work, where consistent shift response matters as much as raw horsepower. This translates to smoother shifts at low RPMs, so operators aren’t fighting the controls in tight quarters or strong currents.

Twin Disc offers a wide range of configurations, including models with hydraulically actuated clutches, electronic shift controls, and optional trolling valves, making it easier to tailor the transmission to the vessel’s job profile. Matching SAE flywheel housing sizes and selecting the right flexible coupling is also a key part of proper setup. Laborde supports these fit-up details during planning to help prevent alignment issues and premature wear.

The strength of this setup goes beyond just matching components. Mitsubishi, Twin Disc, Sewart Supply, and Laborde have worked together to support twin screw applications with a fully integrated, operator-focused solution. Because Mitsubishi marine engines are fully mechanical, Sewart Supply developed an electric-to-pneumatic control solution that bridges the gap between mechanical engines and electronic shift systems. Designed with twin screw applications in mind, this integration gives operators modern shift functionality while maintaining the simplicity and serviceability of mechanical power. This makes the Mitsubishi and Twin Disc combination even more effective in real-world conditions.

For operators focused on durability and uptime, these features translate to fewer breakdowns, better fuel efficiency, and improved handling at low speeds.

Compatibility also extends beyond just horsepower and torque. Bellhousing alignment, shaft coupling, and control system integration are all well supported by Laborde during installation and repower planning. With factory alignment kits and decades of field data, Laborde can spec the right transmission to match Mitsubishi marine engines without unnecessary adaptation or downtime.

This is a marine gearbox that’s already in service, moving tonnage every day. Operators choosing this setup gain the benefits of both systems: the longevity of Mitsubishi’s mechanical platforms and the shift reliability and torque handling of Twin Disc marine gear.

What Are The Advantages of Twin Disc Transmissions?

Many operators who spec Mitsubishi marine engines choose Twin Disc gears. More than mere brand alignment, it’s about how these transmissions perform under real operating conditions: high loads, tight turns, long hours, and short-handed crews.

Here’s what makes Twin Disc transmissions stand out on the water.

Built for Heavy Loads

Twin Disc marine transmissions are built to handle continuous-duty torque, which makes them an ideal match for Mitsubishi’s A and R series engines. These engines are known for their steady torque output at lower RPMs, particularly in the S12A2, S12R, and S16R platforms. Twin Disc units use heavy-duty gears and bearings, and include built-in safeguards like oil cooling and pressure regulation to prevent damage during sustained high-load use.

Smooth, Responsive Shifts

Operators in tight waterways or working near docks can’t afford hesitation at the controls. Twin Disc transmissions provide fast, precise gear engagement with hydraulic clutch systems designed for consistent performance, even under strain. Whether you're holding position in current or backing down with a barge, that responsiveness translates to better control and fewer incidents during tight maneuvers.

Reliable Under Pressure

Like Mitsubishi engines, Twin Disc marine gearboxes are designed with long-haul reliability in mind. They’re commonly used in commercial and military applications, and many units in the field have logged tens of thousands of hours without requiring full rebuilds. Paired with Mitsubishi’s low-maintenance mechanical engines, they form a propulsion system that keeps running when others fail, particularly in under-crewed or remote operations.

Serviceability and Support

Twin Disc maintains a robust support network across the U.S., and Laborde stocks the parts operators need most, including clutch plates, control valves, seal kits, and more. These transmissions don’t require proprietary diagnostics, so experienced marine techs can service them in the field without waiting on factory tools or software updates. That cuts downtime and gives operators more control over their own maintenance schedule.

How Do Twin Disc Transmissions Compare to Other Marine Gear Options?

Operators weighing transmission options for Mitsubishi engines often look at brands like REINTJES, ZF, and Twin Disc. Each has a solid reputation in commercial marine. For inland operations, particularly on high-hour vessels in remote or labor-constrained areas, Twin Disc stands out for its practicality in the field.

-

Serviceability

Twin Disc marine transmissions are designed to be maintained without OEM-specific software, allowing most marine techs to handle clutch adjustments, seal replacements, or control servicing using tools they already carry.

-

Support

Twin Disc has long-established parts distribution and service presence across the U.S. inland corridor. That means less downtime waiting on hard-to-find components and more consistency when it comes to maintenance planning.

-

Familiarity

Many crews already have experience with Twin Disc systems, which helps reduce error during inspections, routine maintenance, or troubleshooting. And because the transmission’s mechanical logic is straightforward, it's well-suited to vessels running lean crews or rotating personnel.

In harsh operating conditions such as muddy rivers, high-debris waterways, and high-cycle barge pushes, simplicity and responsiveness often matter more than advanced control systems or digital integrations.

What Maintenance is Required for Twin Disc Marine Transmissions?

Twin Disc transmissions are known for their durability, but like any mission-critical component, they need regular attention to keep performing. Fortunately, maintenance is straightforward, and crews don’t need specialized training or OEM software to stay on top of it.

Routine maintenance includes fluid level and condition checks, clutch pressure inspections, and monitoring for early signs of wear in seals and gaskets. Twin Disc recommends oil and filter changes at scheduled intervals, along with borescope inspections of critical components like clutch plates and oil coolers.

Monitoring oil temperature and pressure during operation can also help identify early issues, particularly on vessels running long duty cycles or variable loads. Newer models are increasingly compatible with condition-based maintenance (CBM) strategies, using sensors and digital controls to support predictive service plans.

Laborde stocks the right parts in the regions they serve, including clutch plates, filter kits, seal sets, and control valves. These are the components that often cause delays when not locally available. Crews can call on Laborde’s service network for scheduled maintenance, emergency repairs, or troubleshooting without waiting on a factory tech.

Because Twin Disc gear doesn’t rely on electronic diagnostics, even green crews can handle basic checks with standard tools. That makes the system easier to manage over time, especially for operators dealing with tight labor or high turnover. In the field, simplicity is often the best insurance against downtime, and Twin Disc marine transmissions are built with that in mind.

When to Consider a New Transmission

Transmissions don’t fail all at once. Most issues develop gradually, such as harder shifts, slipping under load, or long delays in sourcing basic parts. For operators running Mitsubishi engines, here’s when it might be time to think seriously about replacing or upgrading the transmission.

During a Repower

If you're already planning to repower a Mitsubishi engine, it makes sense to evaluate the transmission at the same time. Matching a new engine to an old gearbox can create problems later on. Gear ratios might not align, or the transmission may not be rated for the torque curve of a newer platform. In repower jobs, misalignment, outdated shaft angles, or cramped space can make integration a challenge. In many cases, the solution is a custom coupling, modified mount, or alignment system that allows for clean install without structural changes.

If You’re Running an Outdated or Unsupported Model

Older or discontinued marine transmissions may still run, but sourcing parts can become a major hurdle. Some OEMs have reduced or ended support for legacy models, and in many cases, parts must be sourced overseas or rebuilt by third parties. If you're spending more time tracking down components than running the vessel, it may be time to upgrade to a modern Twin Disc unit with better support.

When Performance Becomes Unpredictable

Shifting issues, overheating, or fluid leaks under load are all signs that internal components may be nearing the end of their service life. In many cases, the cost and time required to rebuild outweigh the benefits, particularly when downtime puts contract schedules at risk. Operators often decide to replace rather than repair when the transmission becomes a bottleneck in an otherwise healthy propulsion system.

When Part Lead Times Are Growing

Even if your marine transmission is technically sound, delays in sourcing replacement parts can sideline the vessel longer than expected. Twin Disc’s domestic parts network and strong U.S. support give it an edge in this area. For operators already dealing with labor constraints or tight dry dock windows, that availability can tip the scale in favor of a new install.

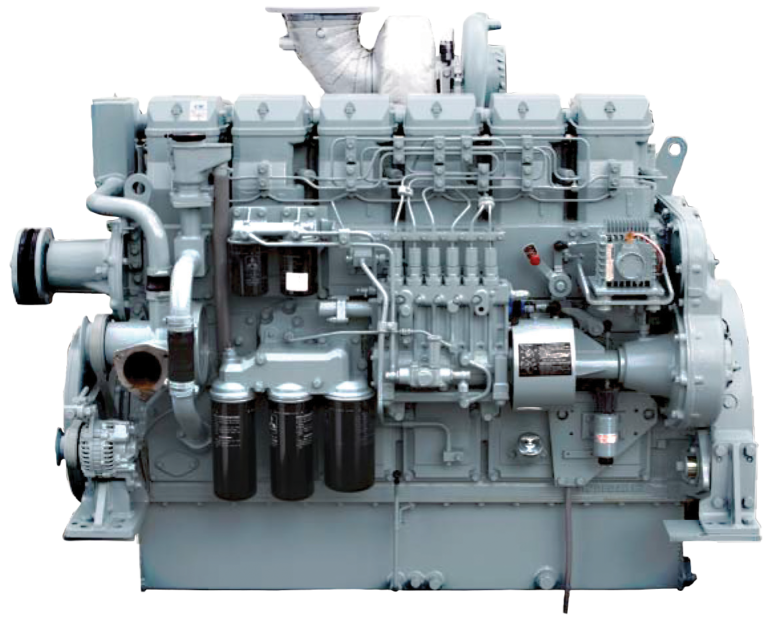

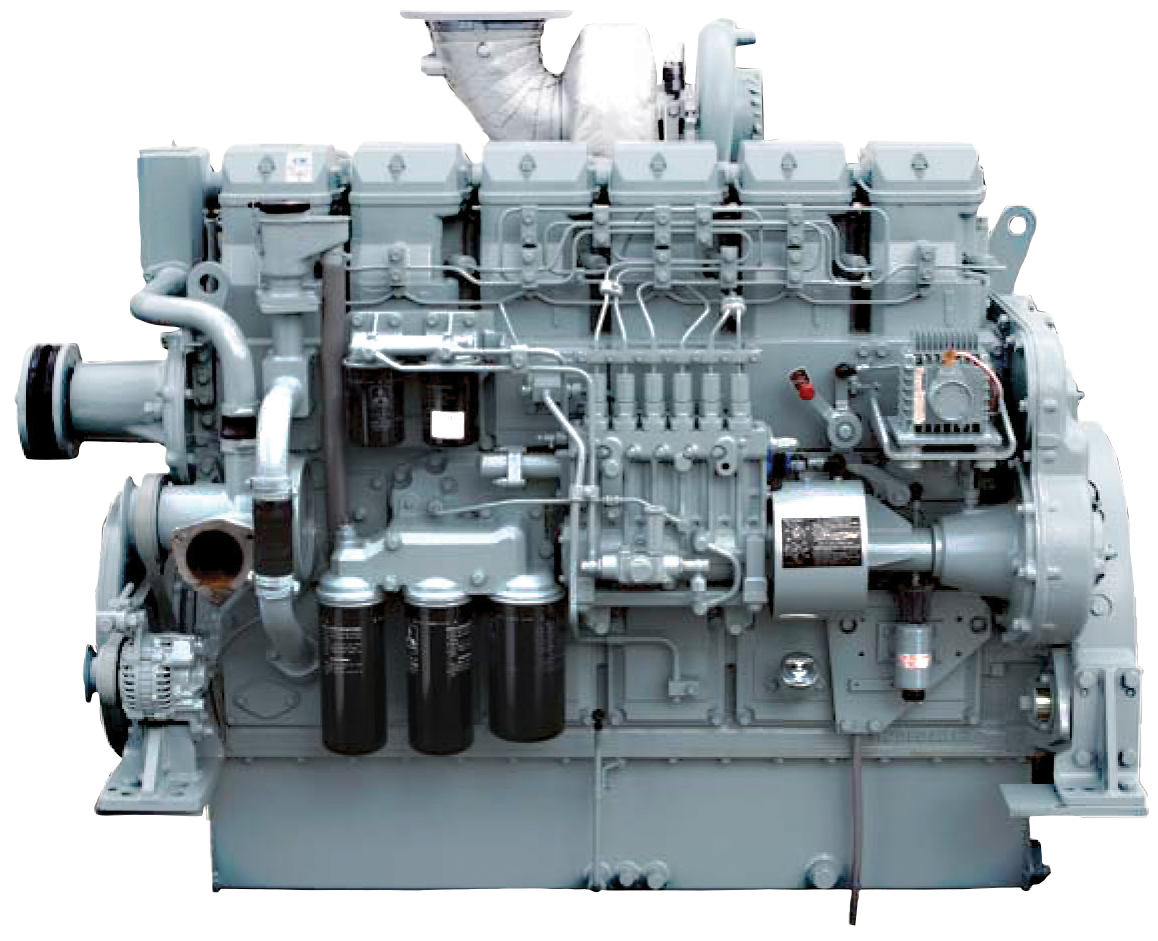

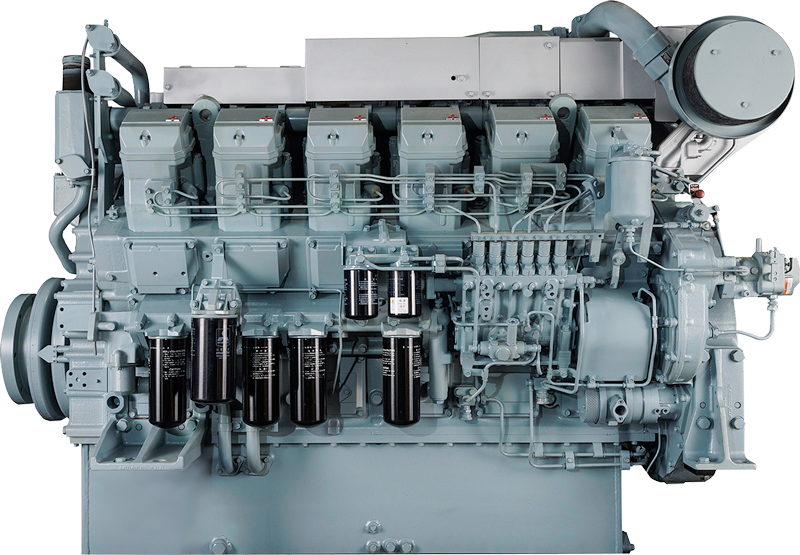

Twin Disc MGX-5321DC

Twin Disc MGX-5321DC

Why This Combo Keeps Showing Up in the Field

Operators are looking for equipment that holds up. Mitsubishi engines paired with Twin Disc marine transmissions have already proven themselves across the inland market, with thousands of hours logged on vessels that can’t afford surprises. The compatibility is solid. The performance is consistent. And the long-term support is there when it’s needed.

-4.png?width=1000&height=600&name=Untitled%20(1000%20x%20600%20px)-4.png) Amelia Ray Photo: Thordon

Amelia Ray Photo: Thordon

In one repower project, a 25-year-old offshore support vessel replaced its outdated powertrain with a Mitsubishi S6R2 and Twin Disc MGX-5321DC. Tight clearances and legacy driveline constraints required a custom coupling and re-pitched propeller—but the payoff was immediate. The vessel gained smoother shifting and improved responsiveness, and crews reported a 20% boost in fuel efficiency.

"Through the years, Sewart & Laborde Products have partnered to successfully deliver many propulsion packages for the inland push boat market, providing operators and shipyards with equipment that is easy to install, easy to maintain, and built to last. This partnership is backed by a strategically located inventory designed to keep vessels operating at their best." - Brian Cheramie from Sewart Supply

If you’re thinking through a repower or weighing options for a new build, it’s worth taking a closer look at this combination. Laborde works directly with operators and shipyards to ensure the marine transmission and engine are matched to the demands of the job, not just the specifications on paper.

EXPLORE OUR MITSUBISHI LINEUP