Proven mid-range power, responsive handling, and real-world reliability make these Scania engines a smart fit for pilot boats.

Maritime pilots work in demanding conditions that call for engines built to perform. Quick acceleration, reliable torque, and consistent uptime are essential for keeping operations on schedule and avoiding setbacks.

The Scania DI16 and DI13 have become trusted choices for pilot boat operators across the industry. Known for their compact design and strong mid-range performance, these engines handle the stop-and-go nature of pilot work and the unpredictable conditions that come with it.

This guide covers what sets these engines apart, how they perform in real-world marine environments, and why so many pilot vessels are powered by Scania.

What Makes the Scania DI16 and DI13 Ideal for Maritime Pilots?

Pilot boats have a specific job, and that’s getting pilots to and from incoming ships quickly and safely. Engines need to deliver strong acceleration, smooth maneuverability at low speeds, and enough torque to move with confidence under load.

Both the DI16 and DI13 are designed for commercial marine duty and use Scania’s EMS engine management system with XPI extra high-pressure common-rail injection. This combination provides precise fuel delivery and a flat power curve that keeps output steady across a wide RPM range. For pilot boats that idle, accelerate, and stop multiple times during a shift, predictable power means operators can rely on the same performance every time the throttle is adjusted. That responsiveness helps pilots place their boats cleanly alongside moving ships and return to cruising speed without delay.

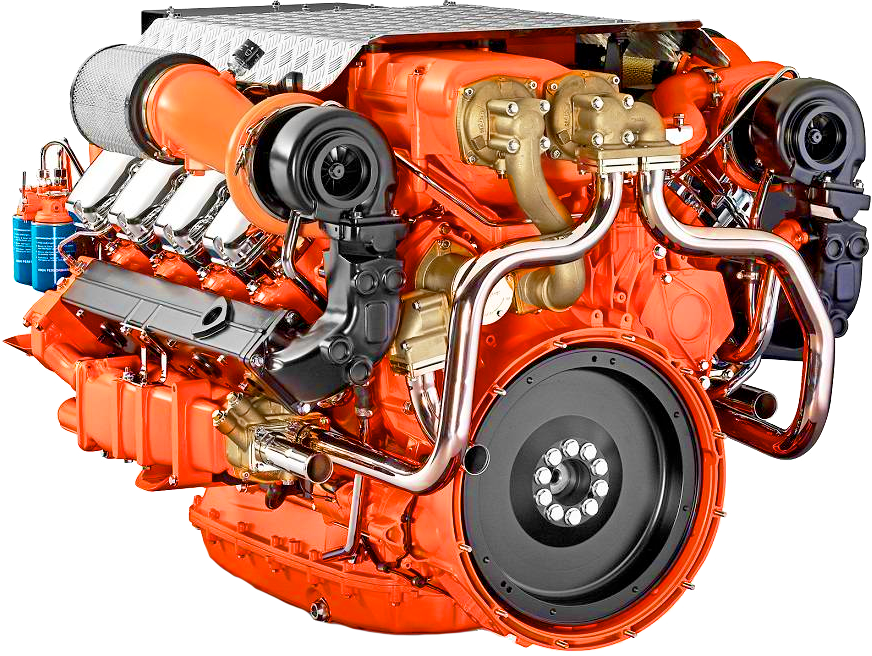

The DI16 is a 16.4-liter V8 with power ratings reaching 846–882 kW, making it well-suited for larger pilot vessels or heavy-duty operations that demand high torque and horsepower. The DI13 is a 12.7-liter inline six with a smaller footprint and a dry weight around 1,285 kg in a 441 kW configuration. It provides strong mid-range power in a compact package, making it ideal for smaller boats or operators who prioritize fuel efficiency. Together, the DI16 and DI13 give pilot operators the flexibility to match engine power to vessel size and workload instead of being forced into a single solution.

How do Scania DI16 and DI13 engines perform in rough conditions?

Scania DI13

Scania DI13

Rough water is part of the job for many pilot boat engines. From sudden shifts in weather to choppy harbor entries, pilot vessels often operate in conditions that put extra stress on every part of the drivetrain.

The DI16 and DI13 are built to deliver reliable starts and stable performance across a wide temperature range, from freezing pre-dawn departures to hot summer shifts. Torque delivery remains steady under load, which matters when a vessel is climbing through heavy chop, holding position in current, or pivoting tightly along the hull of a moving ship. That level of consistency translates directly into control and stability, helping pilots complete transfers safely and stay on schedule.

Real-world applications back this up. Pilot boats powered by twin DI16 packages have recorded sea-trial speeds above 30 knots, showing that these engines deliver both the speed and handling required for demanding pilot transfers.

What Are the Fuel Efficiency Benefits of Scania DI Series Engines?

Fuel efficiency is critical for pilot boats, which often run frequent short trips with constant throttle changes. Cutting fuel consumption without losing performance reduces long-term costs.

The DI13 is often chosen by operators focused on economy in lighter-duty roles, thanks to smaller displacement and optimized fuel mapping that reduces fuel burn during idle and low-speed maneuvering.

The DI16, while larger, still performs efficiently at higher loads. Its advanced EMS system and extra high-pressure fuel injection ensure cleaner, more complete combustion. This technology atomizes fuel for a more efficient burn, maintaining steady consumption and reducing visible smoke even when operators push for higher torque. That makes it possible to meet the demands of larger pilot vessels without excessive fuel penalties.

How Do Scania Marine Engines Compare to Other Brands for Pilots?

When evaluating marine engines for pilot boats, power-to-weight ratio, service access, and emissions compliance all factor into the decision. Scania engines strike a balance across all three.

The DI16 and DI13 are built on compact platforms, reducing footprint and simplifying installation. Their lighter weight compared to many engines in the same power class allows for greater flexibility in hull design and performance tuning. Service access is another benefit. With fewer moving parts and accessible components, maintenance is faster and less labor-intensive, helping keep downtime to a minimum.

From an environmental standpoint, Scania engines meet current emissions regulations without complex aftertreatment systems. That lowers the risk of filter or sensor failures and simplifies compliance.

What Maintenance Is Required for the Scania DI16 and DI13?

.jpg?width=2000&name=LBP-Houston-LFST_172%20(4).jpg)

Like all high-performance marine engines, the DI16 and DI13 require routine maintenance, including oil and filter changes, coolant checks, valve adjustments, and inspection of belts, hoses, and injectors. Scania designs its engines with accessibility in mind, keeping service points easy to reach even in tight spaces. This reduces labor time and makes scheduled maintenance more manageable.

Laborde Products supports Scania engine owners with dedicated parts sourcing, service coordination, and technician access. Whether it is diagnostics or parts replacement, Laborde’s network helps keep downtime low and pilot boats in service.

Built for the Demands of Pilot Work

The Scania DI16 and DI13 have earned a reputation for reliability, quick response, and strong fuel efficiency. These are the qualities every maritime pilot operation depends on. With proven performance in tough conditions, straightforward maintenance, and support from Laborde Products, they continue to be a trusted choice across the industry.